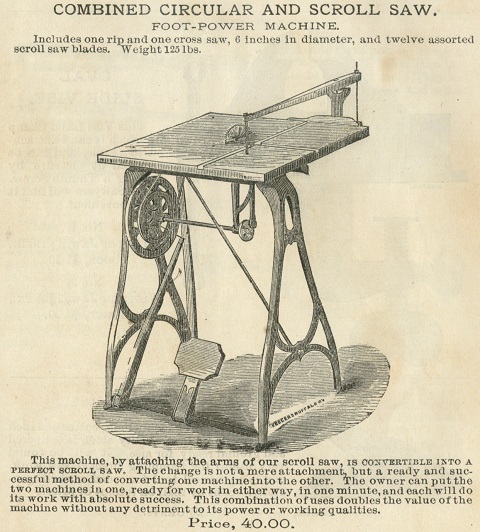

The Barnes Combined Machine was an early introduction (about 1876) that was made up to about the mid 1920’s. It got its name from basically being a table saw with six inch blades that was offered with a full size scroll saw and/or a boring machine attachment. The scroll saw attachment had the same capability as the #2 velocipede/#7 scroll saw and the boring attachment had a scroll chuck with 3/8 inch capacity. Dado and molding cutters were available as was a grindstone that could replace the saw blade on the mandrel in later models providing even more capability. During the time it was made, it evolved from a very light weight machine at about 125 pounds to double the weight as a result of a heavier frame and large and massive flywheel. (This evolution to a more robust design was typical of many of the Barnes machines.)

Researching the evolution of foot powered machinery, especially early versions like the initial combined machines, is a challenge as early catalogs are limited, catalog cuts somewhat inexact renderings and designs were evolving. In 1995, a very well done article was written for the Early American Industries Association journal on Barnes foot powered machinery. Today it still remains the most authoritative source of information on this subject. Here is a link to parts of that article Barnes Article

Since that article was written, two examples of what is felt to be the first version of the combined machine have surfaced and differ somewhat in design most noticed in that these new machines do not have a sliding table that has been well documented and generally considered a “Type 1” or first version. This change is based on one of these two non-sliding table top machines having a serial number of 345 and an early catalog cut of this style surfacing in a non Barnes 1876 catalog. (see below). Also two Barnes catalogs from May and November, 1877 already show the second type (Type 1A) with the sliding table suggesting the Type 1 was very short lived. A sliding table top version with a serial number of 1921 (show below) should help substantiate the sliding table top model as coming later.

So based on this new information, would suggest that the non-sliding top be termed a Type 1 and the sliding table top version now termed a Type 1A. With this in mind, there would now be four types with an estimated total of over 10,000 manufactured – two of the lighter weight models and two of the much heavier ones.

In addition to the weight, the two early types used a small treadle and wooden return spring while the last two used a full size treadle, a coiled metal return spring and the patented “belt gearing” or flat belt with holes. (Belt gearing virtually eliminated slipping seen with small round belt machines.) Originally offered in the first type at $40 with the scroll saw, the price increased with the type 1A to $35 for the saw alone and $50 for the saw with both the scroll saw and boring attachment until the end of production.

To see one of the last models in action you can Google “Barnes Saw” to find several YouTube videos including this one with Roy Underhill of the Woodwright’s Shop Combined Machine

Next is a shot of an unrestored type 1A machine serial number 1927. It had a sliding table top and also used the original light duty frame and treadle. There is some difference in the way the power was transmitted to the saw mandrel and the scroll saw.

The short pedal in the center on the square rod across the front caused the longer wood arm to the left to pull a rope that was connected to a ratchet that engaged and drove the small flywheel. That flywheel had a round belt to the saw mandrel and also a wooden pitman arm for the scroll saw attachment. The wooden return spring at the rear had a rope that went to a take up wheel that reset everything – yes at lot of moving parts and pieces!! (This drive/return mechanism was the same as in other early Barnes machinery.) And yes, the drive pulley on the mandrel did stick up above the table top.

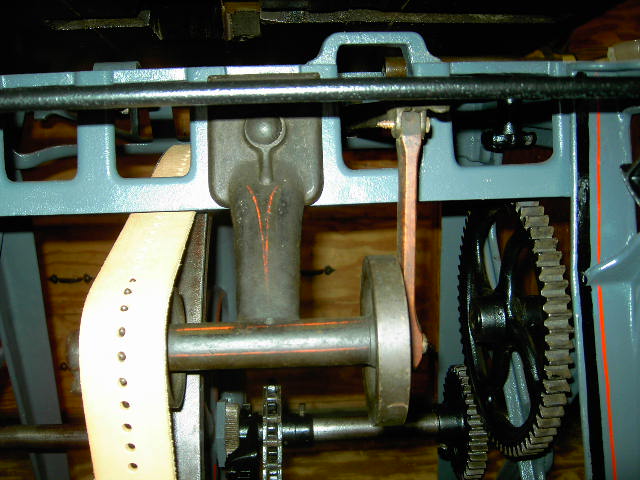

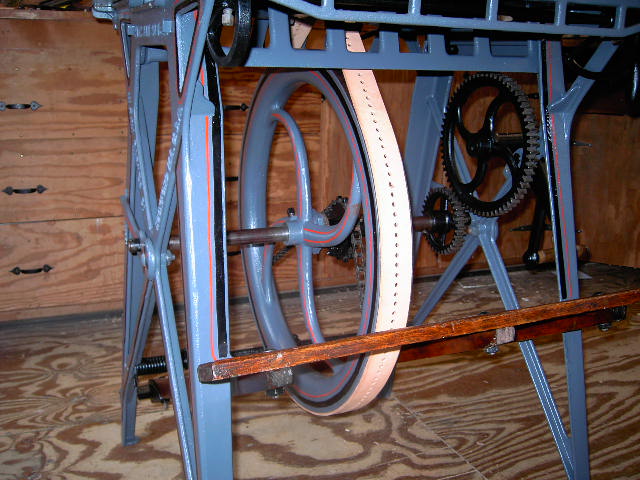

Here are some shots of the last type made – type 4 serial number 7779. (The type three was similar but used somewhat lighter legs.) First shot is “as found in a barn” and then what she looked like after restoration.

Heavy flywheel and true treadle that powered the drive belt with holes to the saw mandrel - hand crank in background