“A machine for moulding edges of brackets, scroll work, panel work, regular and irregular mouldings of all styles with edges up to 7/8 inch in thickness. Articles that look very plain can be made elegant and costly in appearance by the rapid and perfect work of this machine” is how Barnes described the Former in their catalogs. And yes, they did spell moulding with a “u.” This was a vast improvement over a hand plane to decorate wood especially on irregular shaped boards and into corners. The former was introduced by Barnes early in their manufacturing (about 1877) and continued to be made into the 1930’s with likely about 8000 having been made.

“A machine for moulding edges of brackets, scroll work, panel work, regular and irregular mouldings of all styles with edges up to 7/8 inch in thickness. Articles that look very plain can be made elegant and costly in appearance by the rapid and perfect work of this machine” is how Barnes described the Former in their catalogs. And yes, they did spell moulding with a “u.” This was a vast improvement over a hand plane to decorate wood especially on irregular shaped boards and into corners. The former was introduced by Barnes early in their manufacturing (about 1877) and continued to be made into the 1930’s with likely about 8000 having been made.

As with other early Barnes machines, the Former was initially produced using a round belt drive. Later a flat belt version, the Improved Former, was produced that replaced this early round belt style.

When introduced, it was called the Foot Power Former #2. This is likely because it utilized the same base as the #2 scroll saw. (Please see the section on Barnes scroll saw #2) You could buy the top part of the former as an attachment that would fit on the #2 scroll saw base if you already had a #2 scroll saw in your shop. By simply removing the table and arms from the #2 scroll saw, you could mount the Former top and begin work. This option was only available with the early round belt versions.

When introduced, it was called the Foot Power Former #2. This is likely because it utilized the same base as the #2 scroll saw. (Please see the section on Barnes scroll saw #2) You could buy the top part of the former as an attachment that would fit on the #2 scroll saw base if you already had a #2 scroll saw in your shop. By simply removing the table and arms from the #2 scroll saw, you could mount the Former top and begin work. This option was only available with the early round belt versions.

Two versions of the early round belt machine have been noted and differ in the size of the small flywheel and the associated small belt routing pulleys. Complicating this design was the need to transition from the vertical drive of the large pedal drive wheel to the horizontal drive of the cutter shaft using round leather belting. This was achieved by using two intermediate pulleys in the routing of the small belt to the cutter drive pulley.

the size of the small flywheel and the associated small belt routing pulleys. Complicating this design was the need to transition from the vertical drive of the large pedal drive wheel to the horizontal drive of the cutter shaft using round leather belting. This was achieved by using two intermediate pulleys in the routing of the small belt to the cutter drive pulley.

In looking in a very early 1877 catalog which illustrates the Former showing a smaller upper flywheel, we are suggesting that would be the earlier of the two designs. A larger upper flywheel would result in a faster possible speed of the cutter. A faster cutter speed would be more desirable when cutting wood. This evolution from smaller (slower) to larger (faster) would seem more likely than going down in speed. However, this may actually be the reverse.

In looking in a very early 1877 catalog which illustrates the Former showing a smaller upper flywheel, we are suggesting that would be the earlier of the two designs. A larger upper flywheel would result in a faster possible speed of the cutter. A faster cutter speed would be more desirable when cutting wood. This evolution from smaller (slower) to larger (faster) would seem more likely than going down in speed. However, this may actually be the reverse.

When Barnes obtained a patent for “Belt Gearing” in 1886 (# 354,849), it was necessary to totally redesign the Former as the driving mechanism that was common with the #2 scroll saw was now obsolete. This was when Barnes introduced the Improved Former as a dedicated machine and did not offer it as an attachment to the #2 scroll saw anymore.

The Improved Former used a totally new design with the only thing that was still common to the #2 scroll saw was the seat & seat support stem that could still be interchanged. Barnes did begin to label the somewhat different shaped seat support stem on the former with the word “FORMER” but it is common to see a FORMER stem on a #2 scroll saw and vice versa.

Another major difference was a much heavier and horizontal flywheel that drove the flat belt with holes over the sprocket pulley covered in the “Belt Gearing” patent. This horizontal drive eliminated the vertical to horizontal belt drive required on the earlier round belt models plus dramatically reduced any slippage that might occur in the round belt machines.

Another major difference was a much heavier and horizontal flywheel that drove the flat belt with holes over the sprocket pulley covered in the “Belt Gearing” patent. This horizontal drive eliminated the vertical to horizontal belt drive required on the earlier round belt models plus dramatically reduced any slippage that might occur in the round belt machines.

Sometime early in the life of the Improved Former, Barnes switched to a somewhat larger table for the former. While all catalog cuts of the Former show the table top with the early notched corners, Barnes did increase the size of the table somewhat and eliminated the notched corners likely to provide more surface working room.

The table could be raised and lowered to accommodate work of differing heights. By using spacers and rub collars on the cutter shaft, a wide variety of shapes and designs could be produced.

Cutters in a variety of shapes were offered by Barnes from the very  beginning. These “winged cutters” were referred to a “knives” and since they had two edges per wing could cut in both directions. Barnes used this as a marketing tool claiming that the operator could reverse direction of the cutter depending on the grain in the wood. Initially Barnes offered 14 cutter shapes and later increased this to 20. These winged cutters sold initially for $1 to $1.50 and were later all priced at $1.00 each.

beginning. These “winged cutters” were referred to a “knives” and since they had two edges per wing could cut in both directions. Barnes used this as a marketing tool claiming that the operator could reverse direction of the cutter depending on the grain in the wood. Initially Barnes offered 14 cutter shapes and later increased this to 20. These winged cutters sold initially for $1 to $1.50 and were later all priced at $1.00 each.

In addition to these winged cutters, Barnes sold a new style cutter called the New Former Knife. These were solid cutters looking more like small shaper or router cutters of today. These were stackable and by doing this, the operator could produce a wide range of designs. New style cutters were offered for $.50 each.

The cutter arbor on all formers had a diameter of 5/16 inch which was an “odd” size when compared to other shaper cutters. Sometime in the early 1900’s, Delta offered an attachment to make a drill press into a mini shaper. This attachment included cutters that are very similar in shape and design to these New Former Knives and they had a 5/16 arbor hole. These work well on the former and are more common than either of the Barnes styles of knives.

Barnes claimed in their catalogs for the early round belt former that the cutters could reach forty to forty five hundred revolutions per minute. With the Improved Former, this was reduced to twenty to twenty five hundred revolutions per minute.

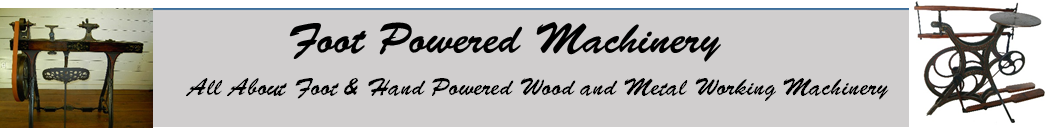

By 1881 a fluting attachment was offered for $3.00 designed for fluting table legs “of usual length and up to 3 inches in diameter.” It had and index plate at one end to make several divisions of a circle and a center arrangement at the other end much like a lathe. The operator would mount the piece to be “fluted” between the two end pieces. The base of the attachment could be adjusted in and out to match the shape of the piece being cut thus allowing a stop or guide that bore against the spindle shaft.

By 1881 a fluting attachment was offered for $3.00 designed for fluting table legs “of usual length and up to 3 inches in diameter.” It had and index plate at one end to make several divisions of a circle and a center arrangement at the other end much like a lathe. The operator would mount the piece to be “fluted” between the two end pieces. The base of the attachment could be adjusted in and out to match the shape of the piece being cut thus allowing a stop or guide that bore against the spindle shaft.  With the work piece in it, the operator would push the attachment and work along and against the cutter. The work piece could then be rotated to the next stop on the index plate.

With the work piece in it, the operator would push the attachment and work along and against the cutter. The work piece could then be rotated to the next stop on the index plate.

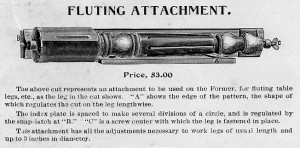

When thumbing through a reprint of a tool & machinery catalog of 1895  from Charles A Strelinger & Co of Detroit MI, I ran across an ad for a Lithological Lathe. A quick search for that on Google got me to a page of ads from Science Vol 11 No 261 from 1888 that actually showed an ad from Barnes for a Lithological or Lapidary Lathe. Looks like all they did was take a Former, modify the table top and add a polishing wheel and a buffer. It would be interesting to see a real life one of these.

from Charles A Strelinger & Co of Detroit MI, I ran across an ad for a Lithological Lathe. A quick search for that on Google got me to a page of ads from Science Vol 11 No 261 from 1888 that actually showed an ad from Barnes for a Lithological or Lapidary Lathe. Looks like all they did was take a Former, modify the table top and add a polishing wheel and a buffer. It would be interesting to see a real life one of these.

Early former models were typically in the “burnt red” color with later models being Barnes gray. All were decorated with pin striping. Serial numbers were stamped in the table top. The Former weighs about 80 pounds and cost initially $25 and was later reduced to $20.

As a part of their marketing, Barnes frequently used testimonials from satisfied customers. Here is one from an 1881 catalog.

Mr. Jas. M. Sheetz, Fisherville, PA says: “The No 2 Velocipede Saw and Former attachment came to hand in good order. They do all, and more, than you claim for them. No cabinetmaker or builder doing any business at all, can afford to do without your machines. Before I tried them I thought the testimonials from parties using them were exaggerated, but it is not so. Besides the No 2 saw and Former, I have seen other of your machines and can recommend them highly.”